Recycling Circuit Board Depopulator For Sale

Business Description

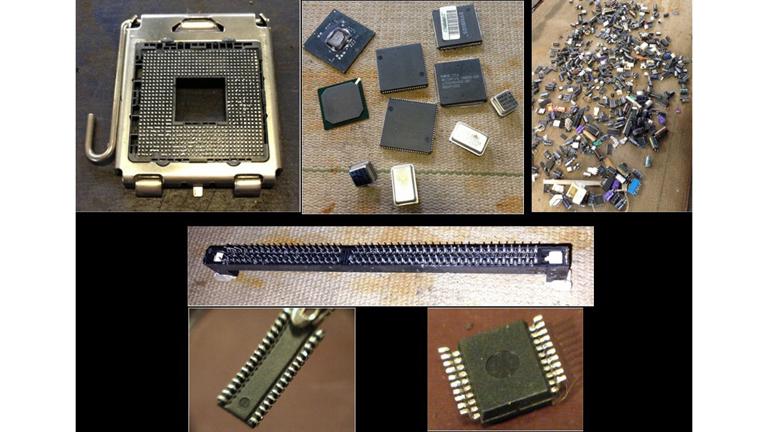

We are selling the first floor model production unit (shown in attached photos), in addition to the 3D CAD drawings, rights, website, specifications to build and sell a circuit board depopulator. There is also a federal carry forward credit of ~$19k and NYS carry forward credit of ~$31k. This is in effect $50k in cash. The depopulator is an innovative, initially patented approach to the rapid removal of electronic parts from printed circuit boards without the use of chemicals. It was designed, developed, and built as a result of Phase I and Phase II SBIR awards from the EPA.

The depopulator applies infrared radiation to a circuit board to melt the solder so that the integrated circuits and other parts on the board can simply be shaken off. The key aspect of this device is its ability to automatically remove circuits without electrically damaging them. It can remove the circuits but leaves them functionally intact. This leads to two modes of operation: Refine and Reuse

In the Refine mode, the depopulator rapidly processes boards at about a 1 ton per 8-hour shift rate. Here the boards are heated as rapidly as possible for maximum throughput. This is the Refine mode, where the integrity of the parts is not important as the throughput rate because it is assumed that the parts will be shipped to a refiner for recycling precious metals recovery. Most of the precious metals lie within the circuit board components, therefore by only shipping the components, the shipping weight and smelting costs can be reduced anywhere from 5 to 7:1. Toxic fumes/pollution will correspondingly be reduced.

In the Reuse mode, the depopulator heats the boards more slowly so as to leave the parts intact functionally for recycling reuse. The throughput will not be as high, but the parts retain their functional integrity.

Additional information is available at our website: advancedrr.com

If interested, please contact the seller through the form on this page.

The depopulator applies infrared radiation to a circuit board to melt the solder so that the integrated circuits and other parts on the board can simply be shaken off. The key aspect of this device is its ability to automatically remove circuits without electrically damaging them. It can remove the circuits but leaves them functionally intact. This leads to two modes of operation: Refine and Reuse

In the Refine mode, the depopulator rapidly processes boards at about a 1 ton per 8-hour shift rate. Here the boards are heated as rapidly as possible for maximum throughput. This is the Refine mode, where the integrity of the parts is not important as the throughput rate because it is assumed that the parts will be shipped to a refiner for recycling precious metals recovery. Most of the precious metals lie within the circuit board components, therefore by only shipping the components, the shipping weight and smelting costs can be reduced anywhere from 5 to 7:1. Toxic fumes/pollution will correspondingly be reduced.

In the Reuse mode, the depopulator heats the boards more slowly so as to leave the parts intact functionally for recycling reuse. The throughput will not be as high, but the parts retain their functional integrity.

Additional information is available at our website: advancedrr.com

If interested, please contact the seller through the form on this page.

About the Business

- Years in Operation

- 12

- Currently Relocatable

- Yes

- Facilities & Assets

- Roboshop is the manufacturer of the Depopulator and specializes in custom and standard material handling systems. Their patented vibratory designs are the basis for conveying, orientation, recirculation and accumulation ranging from very small to large materials and components.

- Website

- https://www.advancedrr.com/

- Market Outlook / Competition

- Competing circuit board parts depopulation techniques involve the removal of parts chemically, which have issues with toxicity and cost of the chemicals, as well as their disposal. The ARR Depopulator does not use chemicals, only relatively inexpensive electricity. Other approaches to depopulation involve manual extraction of the parts, which can be quite slow compared to our Depopulator. In fact, the Depopulator can be up to 50 times faster than manual parts extraction. Another type heats the boards and shakes them off with no regard to parts viability.

- Opportunities for Growth

- Presently much of the electronic waste is shipped to China where the circuit boards are typically smelted to recover precious metals, producing toxic fumes into the atmosphere in the process. There is legislation pending in Congress to bar such exports. In this event, the smelting would be carried out in the US. The Depopulator, by it's ability to reduce the weight of the material to be smelted up to 7:1, will help satisfying the tight controls over smelting in the US.

About the Sale

- Seller Motivation

- The owners are looking to retire

- Transition Support

- Training on the operation of the Depopulator will be provided.

- Financing Options

- Cash, or 33% down with negotiable financing rates and period.

Listing Info

- ID

- 2201259

- Listing Views

- 3329

Attached DocumentsAttachment Disclaimer

Phase_II_Final_Report_Feb_28_2019_02_19_19_rev_2.pdf

Business Location

Listing ID: 2201259 The information on this listing has been provided by either the seller or a business broker representing the seller. BizQuest has no interest or stake in the sale of this business and has not verified any of the information and assumes no responsibility for its accuracy, veracity, or completeness. See our full Terms of Use. Learn how to avoid scams.

Businesses for SaleNew York Businesses for SaleNew York Business Service Businesses for SaleNew York Waste Services & Recycling Businesses for Sale